Introduction

There are a variety of procedures involved in hand surgery — many of which are quick and straightforward, like carpal tunnel decompression and joint injections, normally carried out under local anaesthetic.

However, there is an equally wide range of operations which are far more complex — requiring additional accessories like wrist towers — which not only take longer, but also need more surgical access and require the patient to have a more involved anaesthetic — such as axillary blocks or general anaesthesia.

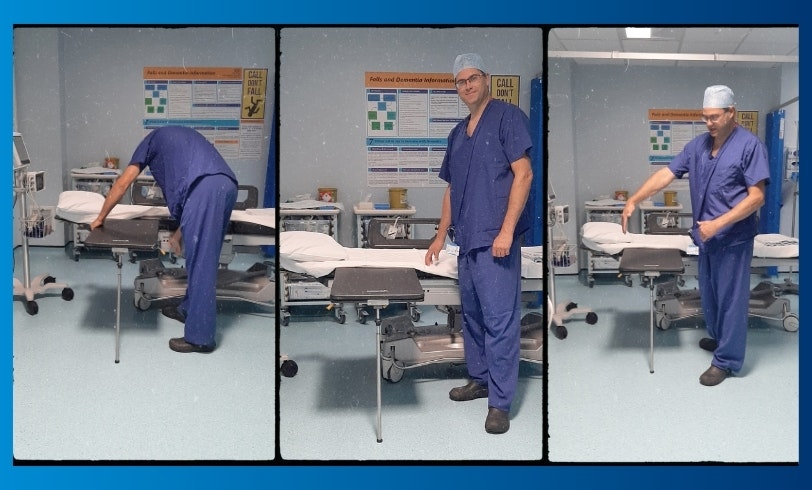

Whatever the procedure, a key element of theatre set up is the hand table attachment for the operating platform being used. But when Consultant Hand Surgeon Mark Brewster and the team at The Royal Orthopaedic Hospital NHS Foundation Trust in Birmingham (ROH) came to replace their table attachments — which had reached the end of their useful life — they couldn't find anything suitable.

Explained Mr Brewster: 'In a busy orthopaedic Trust like ours, it's common to have a range of hand procedures on one list, so you don't want an overly specialised table. We can also have more than one surgeon operating at the same time, so we need to have a model that everyone is happy with — and several of them. Setting up theatres and allocating a specific hand table for an individual surgeon on a particular list would be a real problem.'

Exploring the market

While there are various tables on the market, Mr Brewster could find nothing that answered all of his teams' requirements.

He was still researching when he visited a meeting of the British Society for Surgery of the Hand and learned about another surgeon who was working with a British manufacturer to develop a new hand table — specifically for patients who are awake, and generally in a upright, seated position.

What interested him was not so much the table, but the possibility of collaborating with a manufacturer to build his clinical requirements into a potential new design.

'I got talking to Anetic Aid's Product Manager, Mark Lee, and it turned out the company was in the process of developing a new hand table model, so we met at just the right time. I also found being listened to about potential product design details an interesting experience!'

Mr Brewster explained that the old tables they were replacing were heavy and cumbersome, but the depth of newer models was an issue because they limited the height at which the table could be positioned — often resulting in the framework coming into contact with the surgeon's legs. The depth / softness of the pad also meant there was too much 'play' for his requirements.

'What we were looking for was stability of the table attachment to the trolley with a padded but firm operating surface. We liked the lighter weight of the new version, and that it was a 'direct on' mechanism for attachment, so no need for separate clamps. There was also a detachable leg on the other models, but the trouble was the legs kept being lost...'

And so, The Woodlands Arm & Hand Surgery Table was developed.

Some of the special features built in are:

Reduced overall table thickness

Light-weight model at 6.6kg

Radiolucent

Firm pad of higher density foam that offers a slightly larger surface (L690mm x W540mm) than other models

Laterally-sliding, fixed, fold-away telescopic leg support for easier C-arm access

Outcome

Originally trained in Orthopaedics, Mr Brewster had focused on hands since 2012. He says:

'I find the anatomy of the hand fascinating - the intricacies of the structures: the bones, nerves and tissues. As a surgeon, it is very rewarding to help patients with something that is often fundamental to their independence.

'As a teaching hospital, we can have trainee doctors leaning in to see clearly the complexities of a procedure, which makes the stability so vital.

'Working with Anetic Aid was great because we know the company, and its reputation for reliability. There was just one prototype before we settled on the design: there was nothing like it available previously, and I had been looking for years.

'In total it has taken about 18 months to get to the finished product — it is a real improvement and I am very pleased to have played a part in bringing it to the market.'